Choose the right bush hammer tools

Table of Contents

- What are bush hammer tools?

- What can bush hammer tools do?

- Choose the right bush hammer tools for different equipment

- What roughness can be achieved by using bush hammer tools?

- Operation warnings

- Founding of Actintool

- Shipping & Return

- Customer review

- Check bush hammer category and buy now

What are bush hammer tools?

Bush hammer are metal tools with sharp teeth that can create homogeneous rough texture (CSP 1 to CSP5 on concrete) on the surface of concrete and stone.

What can bush hammer tools do?

- Create slip resistant textures on concrete and stone

Bush hammer tools can roughen the surface of stone and concrete, to create anti-slip finish on pool pavers, patio and other outdoor floors.

- Concrete surface preparation

Bush hammer tools can pulverize the top layers of concrete, to expose the aggregate easily and fully, which increase the bonding efficiency for expoxy coatings and overlays.

- Tough coating removing

Bush Hammer is applied for deep floor pulverization, especially when you expect to peel off the thick surfaces such as thick coatings, very elastic coverings, asphalt, ceramic thin-set, sanded grout, and so on

Choose the right bush hammer tools for different equipment

We have one handheld bush hammer tool available, but in most cases, bush hammer tool needs to fit with an equipment to work. Different bush hammer tool fit with different equipment. It is important to buy the right bush hammer tool for the equipment you have or you plan to have.

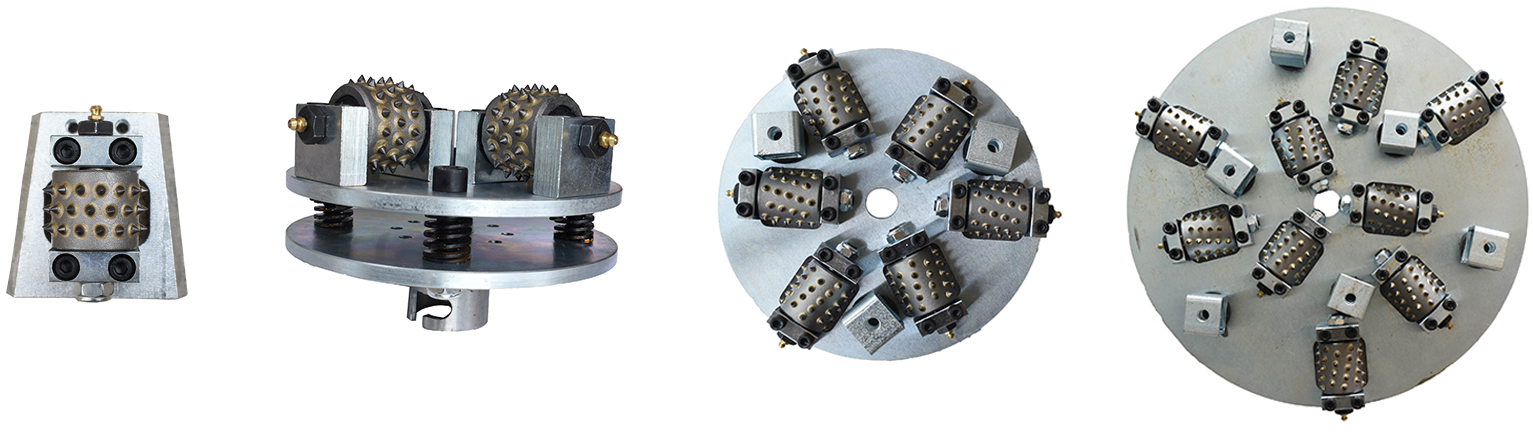

- Bush hammer for rotary & demolition hammer

It is also called bushing bit, busing head, when bush hammer are used on rotary & demolition hammer. It is a useful tool for small area concrete repair, patch and preparation. In Actintool store, four SDS bushing bits are available.

- Bush hammer for angle grinder

It is better to choose angle grinder use bush hammer for areas more than 500 square foot, it can save lots of time. One 5 inch bush hammer plate can cover about 8,000 sqf area. By the way, please choose speed adjustable angle grinder or polisher for bush hammer tools, the suggested RPM is less than 1000, some customers use Makita 9227CB/ 9237CB polisher, Metabo PE 15-30 for their bush hammer plate.

- Bush hammer for floor grinder

For much bigger commercial floors, we have bush hammer grinding plate for floor grinders, like HTC, Husqvarna, Klindex, Diamatic and so on. Buy from existing products or send us an inquiry if you want to customize for your grinder.

- Bush hammer for big machine

Factory use bush hammers are also available for hand and auto polishing machine. The Frankfurt bush hammer block, the 12 inch to 18 inch bush hammer plate are some of the factory use bush hammer tools.

What roughness can be achieved by using bush hammer tools? ?

Different roller bush hammer tools can create different grade of roughness on concrete and stone floor. In other words, bush hammer tools can create CSP 1 to CSP 5 profile on concrete.

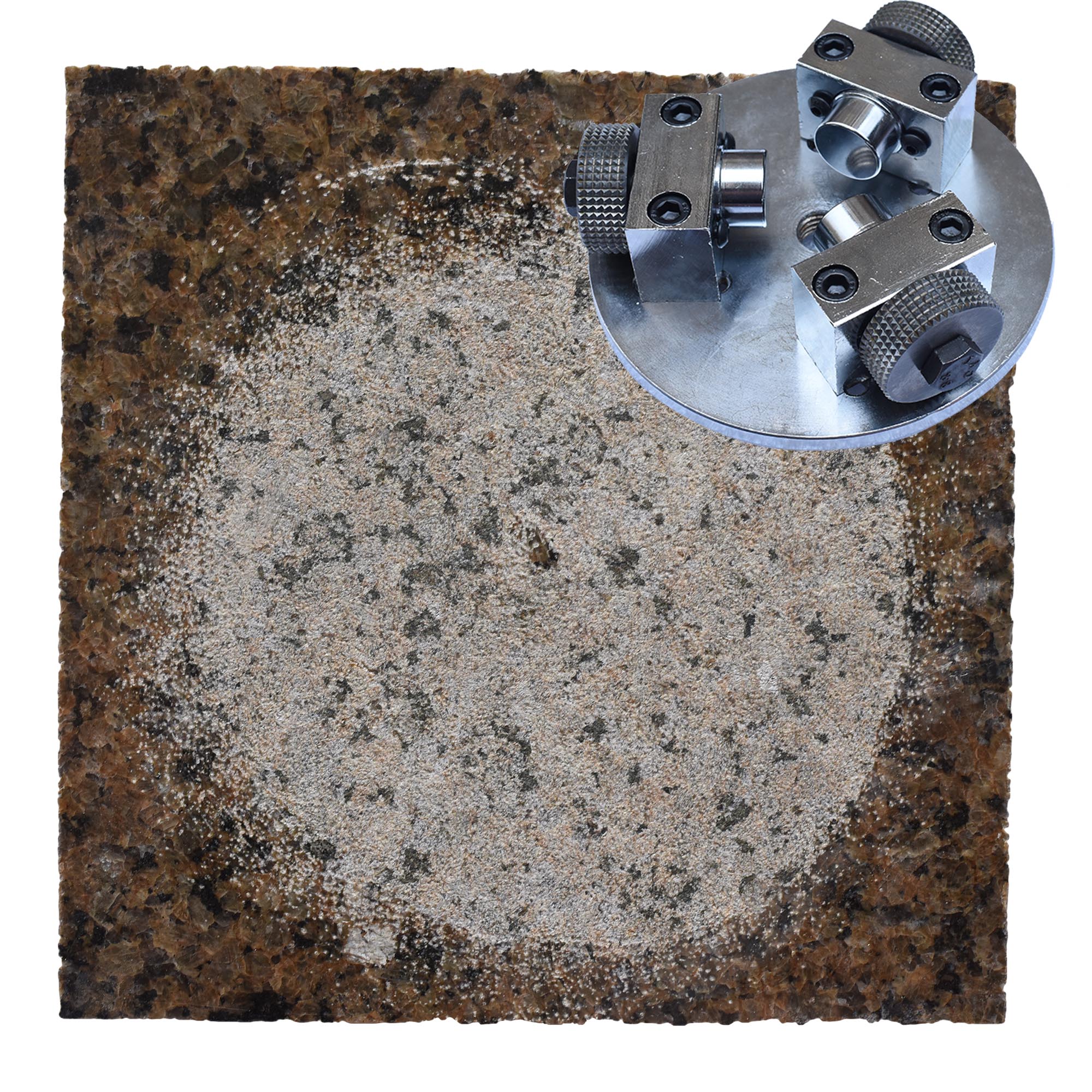

- Sandblasting texture ( CSP 1)

This sandblasting finish is quite fine, maybe finer than CSP 1, can be done by knurling roller. If you’re looking for a slip resistant finish on stair or or other internal stone or concrete surfaces, this is the right one.

The knurling bush hammer can be used on concrete surface before the application of sealers and extra thin films.

The knurling roller is overall cut from tungsten or steel cylinder, there are 312 small teeth on each roller.

15*15cm granite texturing

- Medium bush hammered texture ( CSP 2-3)

This finish is done by star roller, the roughness similar to CSP2-3. If you’re looking for a more slip resistant finish than the sandblasting finish or want to remove not very deep coatings, the star roller bush hammer tool is the right one.

The star bush hammer can be used on concrete surface before the application of thin films (100-250 micron) and high build coating (250 micron-1mm).

The star roller is made of 2 pcs star blade, each blade has 10 teeth.

15*15cm granite texturing

- Coarse bush hammered texture ( CSP 4-5)

This finish is done by lichi roller, the roughness similar to CSP 4-5, it is the most often seen anti-slip finish on outdoor stone and concrete floors. It is a great tool to remove heavy and tough coatings. Most customers choose lichi roller bush hammer for concrete surface preparation, to create CSP 4-5 for high build coating and overlays.

The lichi roller is a metal cylinder welded with some cone shape tungsten teeth, the 30 teeth roller are used for rotary hammer and angle grinder bush hammer tool, 45 teeth roller used for floor grinder and factory use machine.

15*15cm granite texturing

Operation warnings

Please keep the operation tips in mind to make the best use of the bush hammer tools.

- Working Speed under 1000 RPM. Not recommended for high rpm angle grinder, suggested to install bush hammer on speed adjustable angle grinder or polisher, such as makita9227CB/ 9237CB polisher, suggested speed less than1000 RPM. 30 tips bush hammer roller not suggested for three phase walkbehind grinder, too much pressure can break the bearings inside the roller. For three phase grinder, please use the 45 tips bush hammer roller with bigger bearings.

- Do not apply too much pressure on bush hammer. This will prevent roller from stopping and thus decrease the life span of the tungsten steel.

- After each use, please clean up rollers, dry and apply oil to the spindles. It will be ideal to submerge the rollers in oil to prevent spindle rust. Roller tips can be re-dressed with diamond blades when they become inefficient.

Founding of Actintool

Eric Lai is the co-founder of ACTINTOOL, he has been providing diamond tools for concrete and stone floor processing for more than 10 years. Starting as the sales, Eric has won customers’ trust all over the world.

Attended international fairs (such as Italy Verona Stone Fair, Germany Nuremberg Stone Fair, Poland Poznan Stone Fair and Mexico CIHAC Expo).

With cusotmers

Eric working in production zone

Thanks to customer’s increasing trust and continual support, Eric has founded ACTINTOOL to start the manufacturing of diamond tools. As the manufacturer, we can customize products in shortest time according to customers’ requirements, provide satisfied products, fast shipping and refund is guaranteed for defective products.

Shipping & Return

2-6 Days’ Fast Shipping: For US Customers, we will dispatch in 2 business days from US warehouse, customer can receive in estimated 5 days. For Customers outside US and customized products, we ship from China warehouse by DHL, Fedex and etc, Customer can receive in around15 days.

Returns: If your item is faulty or we have sent you something different to what you ordered, return it to us in the original packaging within 30 days and we will give you a replacement or a part refund with shipping cost deducted.

Payment Safety: All transactions are SSL-protected and guaranteed safe

Your Privacy: We will never share your information with anyone.